Smart voussoir traceability starts here

Simplify quality control and secure every step of production

Product Identification & Codes

🏷️Supported Codes

Barcode

QR Code

GS1 DataMatrix

🆔Product Identification

- 🔵Unique Id 360sc

- 🟢Unique Id GS1

- 🌐Protocole GS1 DigitalLink

Production Steps

Internal traceability

🧰Mold management

- Preparation / Commissioning

- Cleaning

- Quality

- Optional carousel management for production handling

Ensure mold availability, compliance, and optimized management, with or without carousel.

🧱Voussoir Preparation

- Mold scan

- Plaque scan

- Rebar scan

Goal: Initialize voussoir identity

🔗Pairing of the rebar

- Scan and associate the rebar with the voussoir

Ensure the identity and traceability of each integrated rebar

🧪Concreting

- 'Ready to concrete' validation

- End of concreting

- Formwork removal

Goal: Trace the entire concrete cycle

🎯Finishing

- Plaque reading

- Paper label reading

- Final quality control

Goal: Quality check & decision

🛠Repair

- CQP diagnosis & history recording

Goal: Traceability even in case of non-conformity

📦Stocking

- Stock entry scan

- Automatic voussoir sheet (PDF) generation

Goal: Official record + document generation

External traceability

🧾Delivery and/or TBM (Tunnel Boring Machine) Reception

- Delivery with reception

- Integrity check upon site reception

- Automatic pairing with the current ring

- Registration in the central database

Complete traceability up to site reception

🏗️Installation & TBM Tracking

- Interactive voussoir map by ring

- BIM integration or 3D viewer

Advanced tracking of installation and digital integration

🎥

Video: Moule-Plaquette-Armature Pairing

Watch how the system pairs each mold, plaque, and rebar to ensure perfect traceability from the very first step.

📊

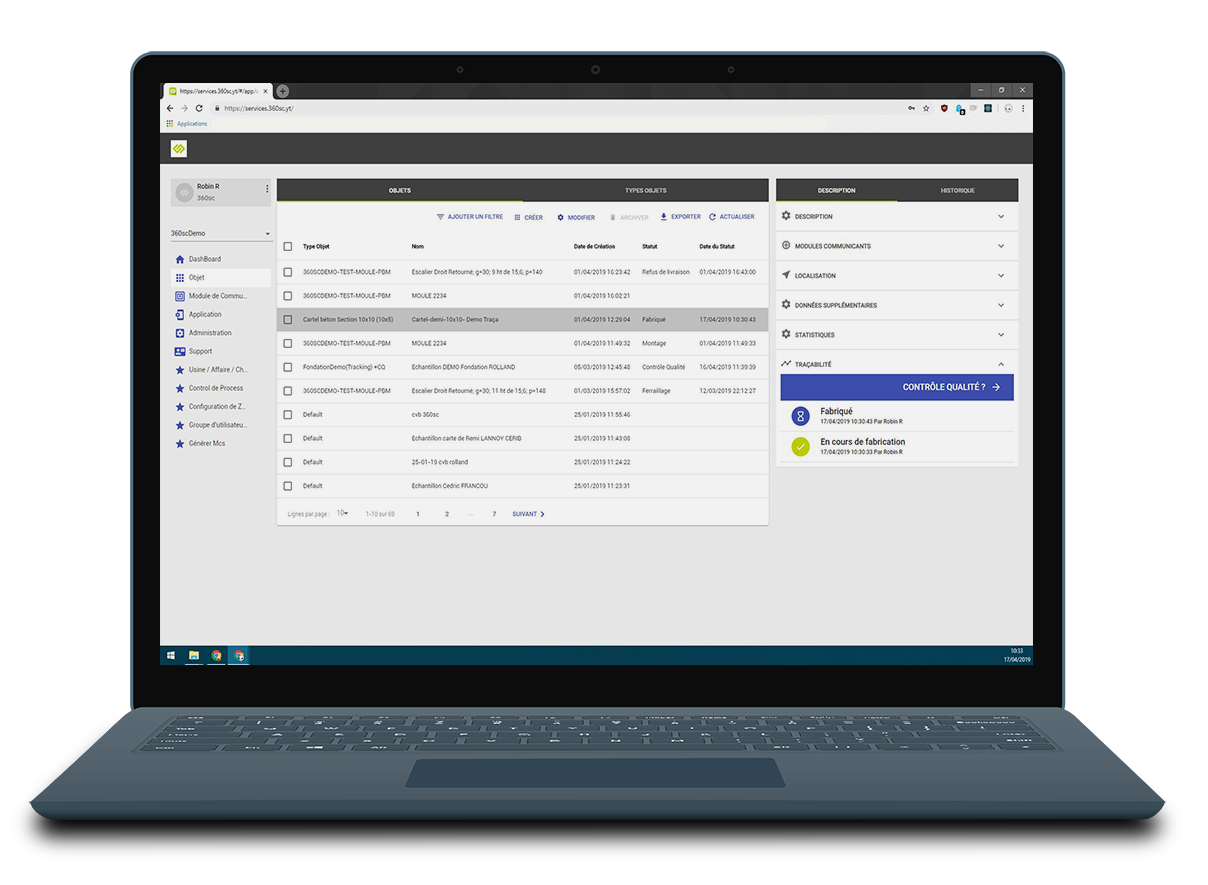

Real-time dashboard

KPIs: compliance rate, batch tracking, advanced filters

A cockpit for quality and production management

🔗

System Connections

Compatible with your existing tools

ERPCRMBIMMESAPI

🔗